![]()

A shopping trip to the H Mart grocery store on Oakland Road in San Jose, California, is a delicious feast for the stomach and for the eyes. The vast selection of products at this Korean supermarket covers the gamut from fresh produce, high-quality meats, and live seafood to sauces, specialty snacks, and authentic Korean side dishes. There’s even a food court with several restaurants where you can sit down and enjoy a hot meal. Our advice? Don’t leave without trying the Korean corn dogs.

Another striking feature of the store is its clean, cohesive aesthetic. The refrigerated cases along the aisles were recently retrofitted with insulated glass doors, complete with sleek black handles and trim to match the store’s giant black wall banners. Thanks to the new, custom, brighter LED lights in the cases, the vibrant colors of the products really pop. It’s like an art museum but with food.

![]() The new case doors are part of a series of retrofit projects that Taper completed for H Mart at five of its California stores. The partnership originated a few years ago when H Mart—America’s largest Asian supermarket chain, with 97 stores—approached Taper for help to address several challenges related to its door-less refrigerated cases. They were highly inefficient, increasing energy costs and carbon emissions. And just as importantly, customers were complaining that the stores were uncomfortably cold.

The new case doors are part of a series of retrofit projects that Taper completed for H Mart at five of its California stores. The partnership originated a few years ago when H Mart—America’s largest Asian supermarket chain, with 97 stores—approached Taper for help to address several challenges related to its door-less refrigerated cases. They were highly inefficient, increasing energy costs and carbon emissions. And just as importantly, customers were complaining that the stores were uncomfortably cold.

“Refrigeration accounts for more than 60% of H Mart’s energy consumption,” said Michael Kim, H Mart’s West Coast Asset Manager. “We wanted to substantially reduce our energy usage and emissions with a case door retrofit.”

A big undertaking with many moving parts

Installing refrigerated case doors has very complex logistics. The timing of several different types of contractor work must be carefully coordinated to minimize disruption to store operations. First, the existing fasciae (logos and other branding attachments to support a uniform aesthetic) on the exterior of the cases are removed. Second, custom-made, form-fitted doors are added to the cases. Third, the existing lights in the cases are replaced with more efficient LED lighting. Finally, refrigeration adjustments are made to accommodate different environmental conditions in the cases due to the doors. To make matters even more complicated, it’s crucial to maintain constant temperatures in the cases before, during, and after the work of each contractor.

It’s precisely this level of complexity where Taper excels, turning logistical challenges into streamlined operations. Taper conducted extensive store walkthroughs and surveys with the H Mart team to determine installation needs and options. On the basis of that research, we designed a comprehensive solution to schedule and manage our experienced installation partners to complete the work—all while minimizing impacts on daily store operations. As a general contractor, Taper was able to source a partnership with Remis, a leading national manufacturer and installer of energy-efficient refrigeration doors designed to enhance product display in retail settings. We’re one of the few energy upgrade implementers that can seamlessly deliver such a complex project, thanks to our deep network of partners and extensive experience with construction logistics.

“We worked closely with Taper to identify the door retrofits that would maximize operational benefits for our stores,” said Kim. “They were great about communicating their proposed schedule for the work and adjusting the schedule to meet our needs.”

To help make the retrofits affordable for H Mart, Taper also handled all the work to secure financial incentives from several local utilities.

An unequivocal success

Challenges inevitably come up with any major installation project. We collaborated with the H Mart team and our installation partners to create effective solutions to several obstacles related to unusual case styles and store layouts. Everything came together without any major hitches, and the project was completed on time and within budget.

“It’s remarkable how smooth the installation was, considering the number of contractors, stores, and doors involved,” said Kim. “They made the process so easy for us. Everything looks beautiful.”

“Working with Taper has been great,” said Isaac Hernandez, installation supervisor at Remis. “What I like about our partnership is how we always work together to resolve any challenges that come up.”

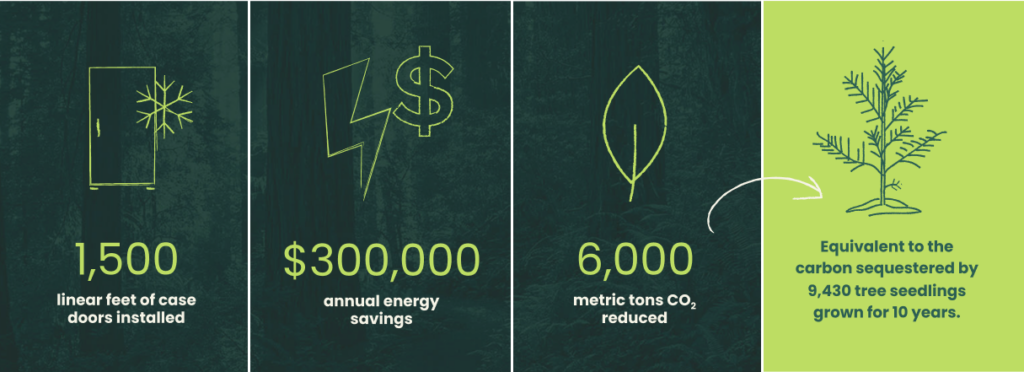

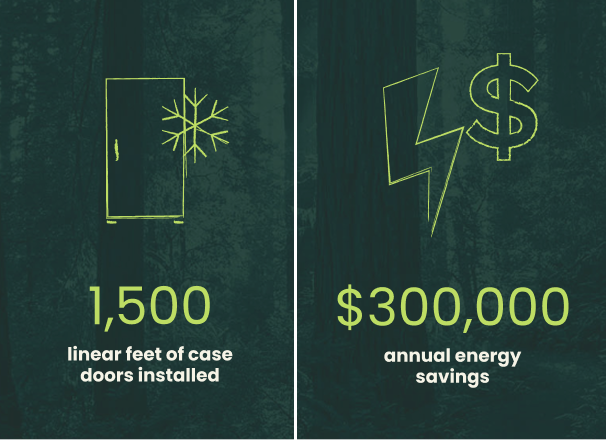

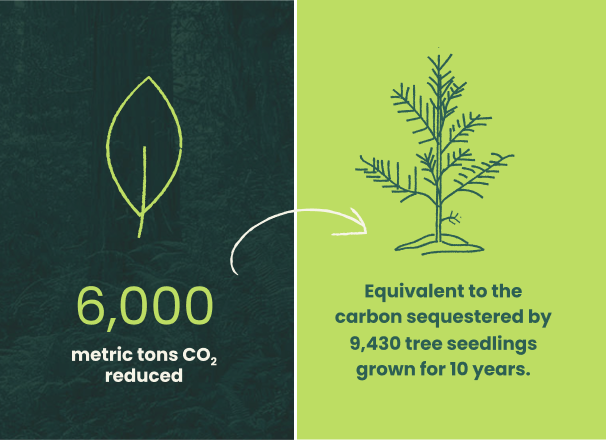

The results are impressive. Across the five California stores, 1,500 linear feet of case doors were installed, yielding nearly $300,000 in projected annual electricity savings. The retrofit is expected to reduce H Mart’s annual CO2 emissions by more than 6,000 metric tons—equivalent to the carbon sequestered by 9,430 tree seedlings grown for 10 years. We secured $70,000 in utility incentives, reducing total project costs by 7%.

The benefits for H Mart go well beyond reduced energy usage, operational costs, and emissions. The cases are better able to maintain consistent temperature and humidity, even in the hot summer months. This increases product shelf life and reduces food waste. Meanwhile, ambient temperatures in the stores are more comfortable. Employees have a better work environment. Customers are more comfortable and spend more time in the refrigerated aisles. The products also look more appealing with the brighter LED lights. The better overall shopping experience translates into stronger sales.

“I see Taper as a key long-term partner in saving energy and working toward net-zero carbon emissions,” said Kim. “I look forward to continuing the partnership. Two thumbs up for Taper.”